Sanaye Chodan Isfahan (SCI)

+98 (31) 424 995 55

Sanaye Chodan Isfahan (SCI)

Moulding lines :

-Automatic HWS molding line

- Semi-automatic moulding line

Sand lines:

Furnaces :

Core-making machines :

Shot blasting :

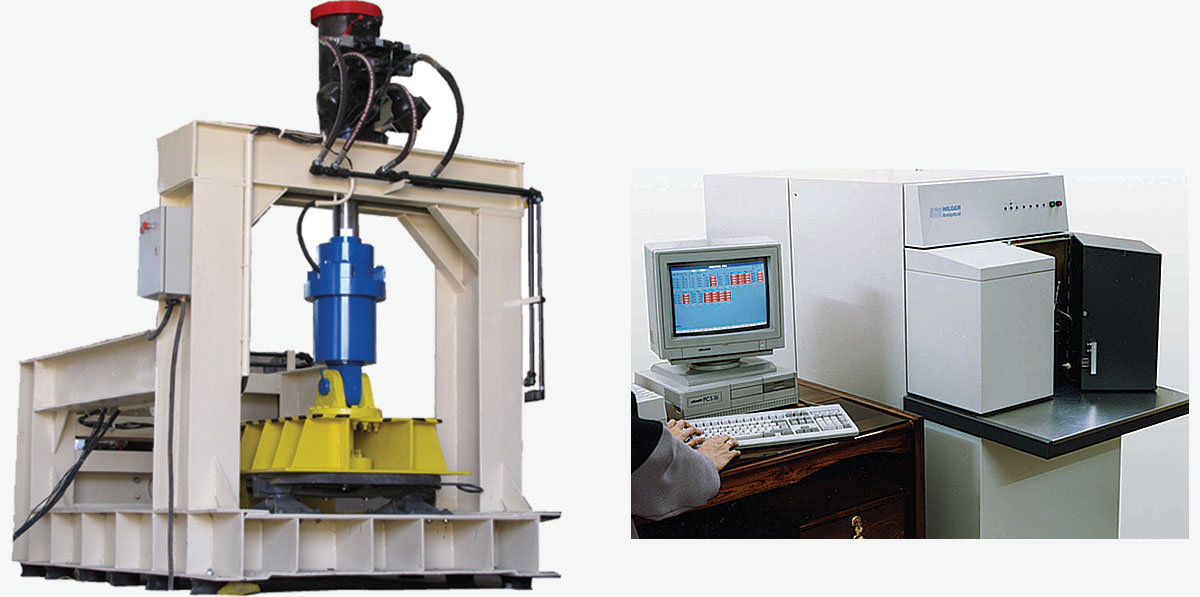

Machining units of SCI has advanced production machineries, such as CNC lathe and Carousel machines and horizontal and vertical milling machines ,and variety of modeling and molding equipments with annual machining capacity of over 5000 tons CNC modeling and molding machines.

SCI ensures maximum quality compliance with quality assurance pocedures using advanced labratory equipement including:

Design and product develpment that exceeds national and international standards

Design and manufacturing necessary for foundry and related industries: