SCI ensures maximum quality compliance with quality assurance pocedures using advanced labratory equipement including:

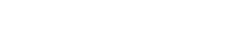

- Quantometer

- Mechanical and Control labratory for microscopic structrual analysis

- Mechanical test including hardness,tensile testing and elasticity,etc

- Non-destructive testing methods including ultrasonic, nodular test,MT

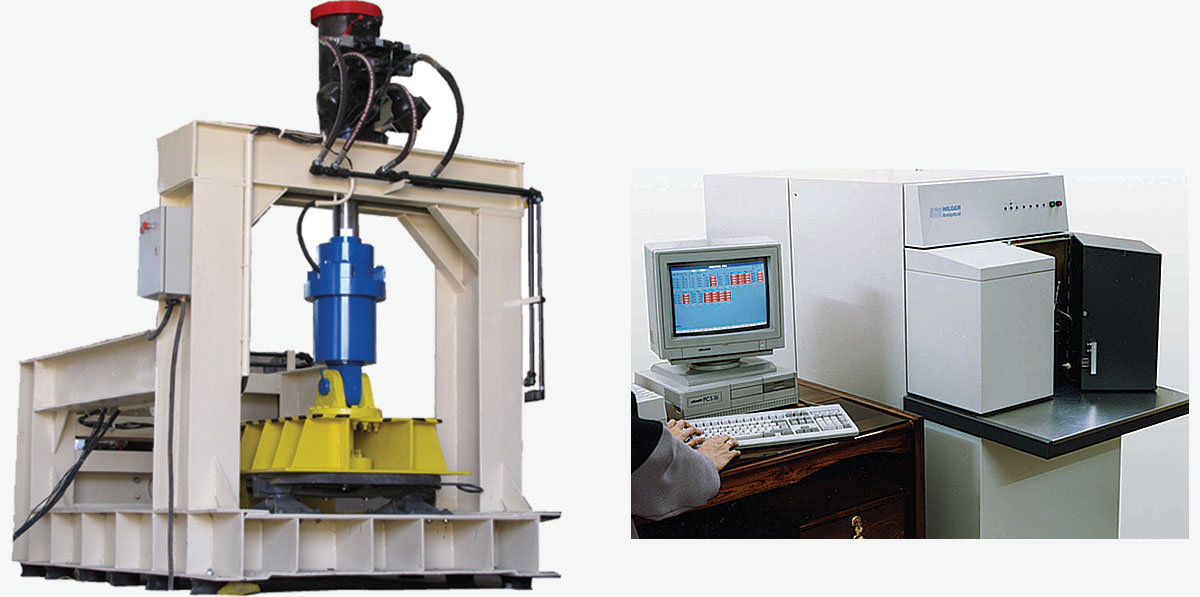

- Dynamic and static testing of fifthwheels to ensure ultimate satisfaction

- Sand and chemical tests to ensure quality during production